This procedure explains the general procedure for maintaining the items in a stocktake batch. However, if you are:

To add and maintain the items in a stocktake batch:

Refer to "Creating a New Stocktake Batch" or "Recalling a Stocktake Batch".

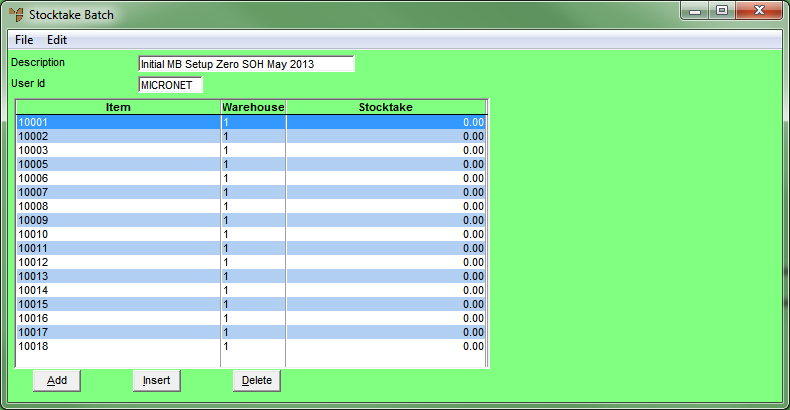

Micronet displays the Stocktake Batch screen showing all the items in the batch.

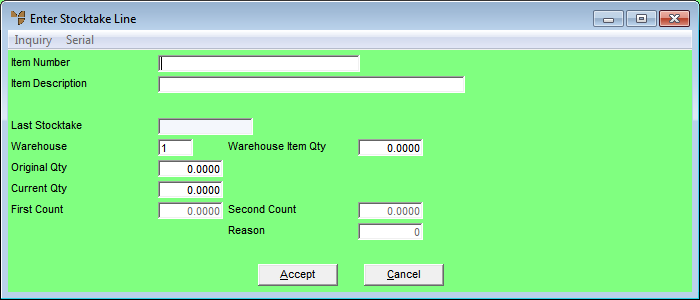

If you selected to add, insert or edit an item, Micronet displays the Enter Stocktake Line screen.

|

|

Field |

Value |

|---|---|---|

|

|

Item Number |

Enter the ID of the item to be added to the stocktake batch, or press Tab or Enter to select an item. |

|

|

Item Description |

Micronet displays the description of the selected item. |

|

|

Last Stocktake |

Micronet displays the date of the last stocktake on the selected item. |

|

|

Warehouse |

Micronet displays the warehouse for the item. |

|

|

Warehouse Item Qty |

2.8 Feature Micronet displays the current quantity of the item in the selected warehouse. |

|

|

Original Qty |

Micronet displays the quantity of the item when the batch was first created. |

|

|

Current Qty |

Micronet displays the current quantity of the item. |

|

|

First Count |

When you have completed the first physical stocktake count on this item, enter the first quantity counted. For stocktake batches where the Stocktake Method is set to Append Stocktake Qty to SOH, this field defaults to zero so you can enter the adjustment amount, e.g. 3 (add 3) or ‑5 (deduct 5). |

|

|

Second Count |

If you complete a second physical stocktake count on this item, enter the second quantity counted. |

|

|

New Bin |

This field is only displayed if Edit Bin Locations is toggled on – see "Stocktake Batch - Edit - Edit Bin Locations". If this field is displayed, you can enter the item bin location. |

|

|

Reason |

If you have created a variance batch and entered a second count of the item, Micronet displays the reason code for the count discrepancy, if any. Stocktake reason codes must be setup in the Class master file – see "File - Class". |

|

|

|

Reference For more information on the First Count, Second Count and Reason fields, see "Entering the Stocktake Count" and "Stocktake Batch - File - Create Variance Batch". |

Micronet saves the details of the item you have added to this stocktake batch and redisplays the Enter Stocktake Line screen so you can continue adding or maintaining items.

Micronet redisplays the Stocktake Batch screen showing all the items added to this stocktake batch.